The Scottish Whisky Research Innovation Centre (SWRI) held a novel “Biotechnology Meets Co-product Innovation Day” on 19th February at their Edinburgh headquarters. Xanthella joined a number of other industrial biotechnology providers to present and discuss options for the Scottish whisky distillers in adding value to their co-products. It is estimated that the Scottish whisky manufacturing produces over 4 million tonnes of co-products in the shape of spent grains and nutrient rich pot ale every year. Traditionally these co-products have been used in farming or simply disposed of, but increasing whisky production and a desire to move to more circular economy measures has prompted the whisky industry to look more closely at its co-products to see if there are better solutions available.

Around sixty people attended the meeting, about half of which were senior management from the whisky industry itself, but there were also a number of representatives from the finfish aquaculture and feed sectors. They were interested in the possibilities of turning whisky co-products into fish feeds, or ingredients for fish feeds, as this would improve the security of supply and displace imports into Scotland. There was particular interest in the possibilities of removing the need to import fish meal. The major challenge in this is scale as the salmon feed companies use large quantities of fish meal or plant proteins, therefore any substitution would require large scale and predictable supply coming from whisky co-products.

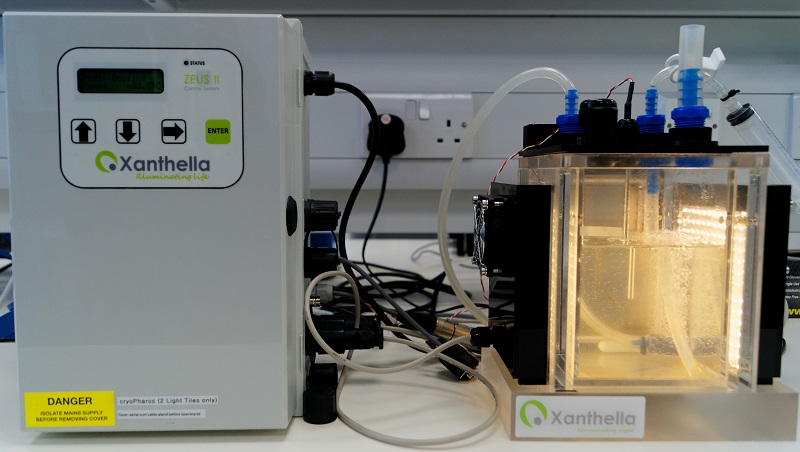

Xanthella outlined the Zero Waste Scotland funded ENBIO project and how this seeks to enhance rural economic activity through integrating fermentation CO2 and nutrients from whisky co-products with growing microalgae for high value products that could be used in Scotland’s aquaculture sector. Essential in this approach is to take full advantage of Scotland’s renewable energy resource. Douglas McKenzie from Xanthella explained their “LISA” (Local Integrated Systems Approach) strategy which seeks to evaluate and integrate local resources using a circular economy approach and shared with the delegates the progress on the Ardnamurchan photobioreactor array being built as part of the ENBIO project.

The meeting closed with a useful and entertaining “speed dating” session where the delegates went round all of the presenting companies and were able to ask them questions around their technologies. The event was deemed a success and particularly interesting because of its cross-sectorial nature.