The ASLEE project is using algal bio-production to rethink the rural economy and establish a new industry that simultaneously strengthens the circular economy. By enabling better use of stranded resources and distillery coproducts as well as using surplus renewable electricity in otherwise grid constrained fragile areas the manufacturing process creates added value services and products.

Remote, rural areas like the Highlands and Islands of Scotland, often have huge untapped renewable sources of electricity but the National Grid was never designed to transmit large amounts of power from diffuse sources located in remote areas. New renewable projects have either to pay for the local grid to be strengthened or face lengthy delays waiting for the District Network Operator (DNO) to upgrade the local grid. Grid weakness also means that existing renewable capacity is often constrained off, reducing income. In Orkney alone, it is estimated that local communities are losing around £2M annually due to problems of grid constraint. Algae have been shown to be tolerant of light intermittency, which means that algal production can provide a base demand justifying additional renewable generation while the submersible LED light sheets developed for the photobioreactor (PBR) system act as a transactive load for grid balancing. Electricity can be used at the most productive times, lowering the costs of algal production whilst also ensuring that electricity generation is maximised in constrained areas, preventing waste of capital resources such as wind turbines.

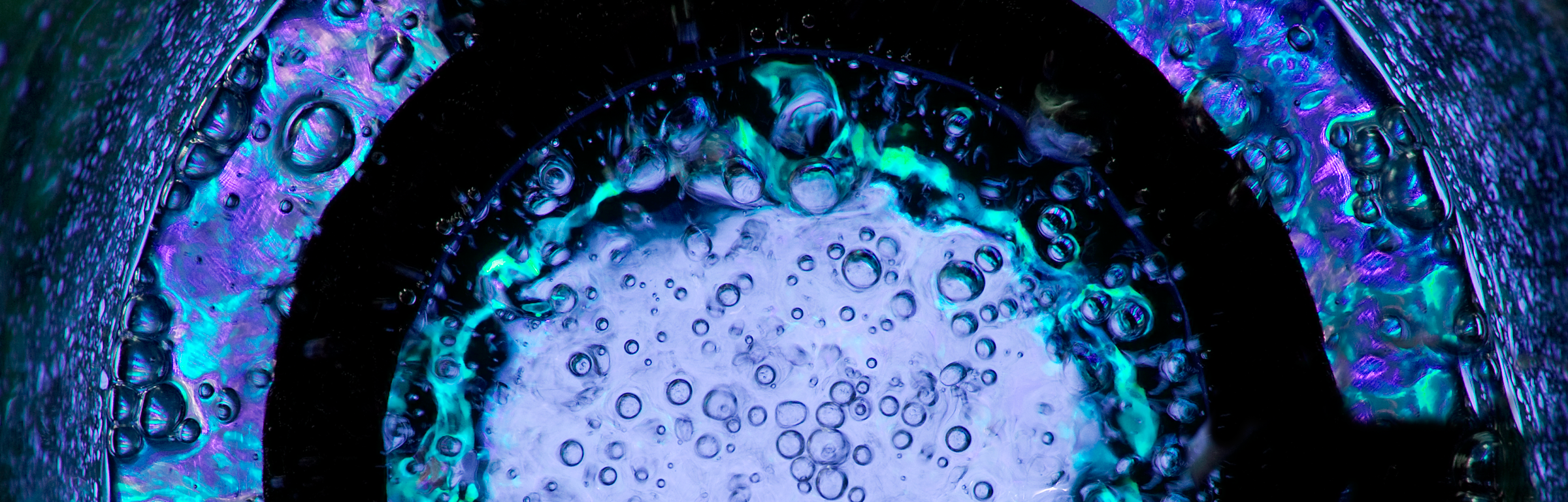

The Pandora PBRs developed in the ASLEE project can be assembled in modular arrays, which are adaptable and can be scaled to make effective and efficient use of local resources. Furthermore, a leasing model for the innovative algal production system is proposed allowing for software and hardware support, rework and repair, ease of equipment management for the user and ensuring correct end of life re-use and recycling of materials.

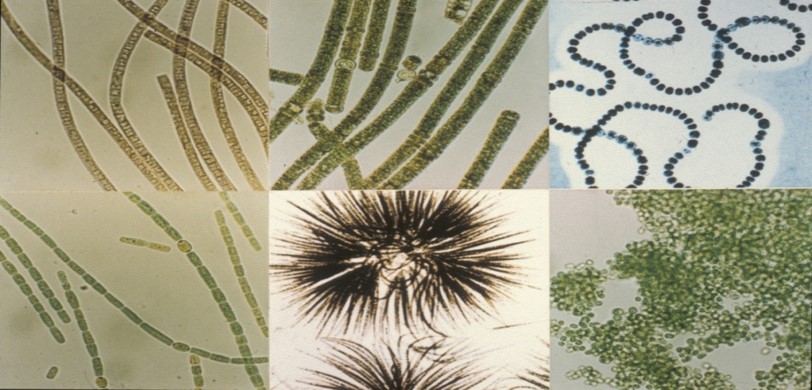

Algal production can also reuse distillery co-products and directly incorporate the available CO2 at the manufacture site, thereby reducing waste and increasing carbon savings for other indigenous industries. The algae produced gives added value as it has many applications including: aquaculture hatchery feed; an additive in fish feeds; nutraceuticals; toxin standards; pigments and biofuels. The whole dynamic system can potentially provide new employment, income from the algal biomass sales, ancillary services to the electricity grid, a facility for contract research and increased carbon savings for other local enterprises.

Thus, using locally available renewable resources in this algal bioindustry results in “mutual benefits, multiple income streams and a positive cycle”- (The Circular Economy – A Wealth of Flows, Ken Webster, 2nd Edition, 2017).