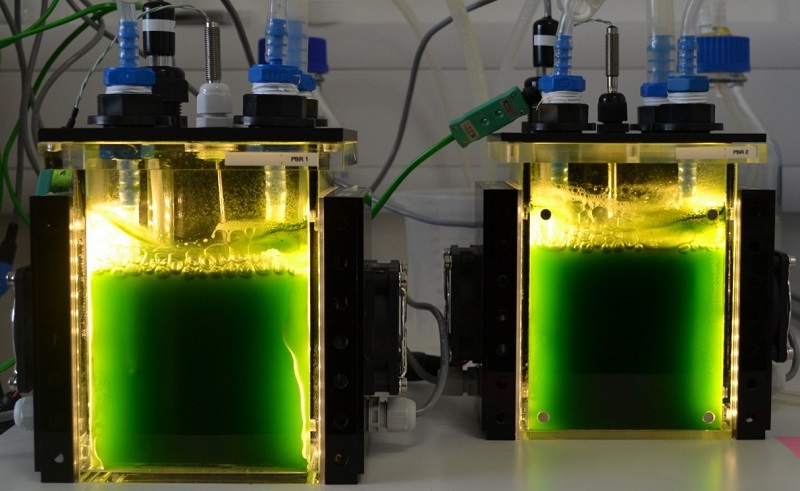

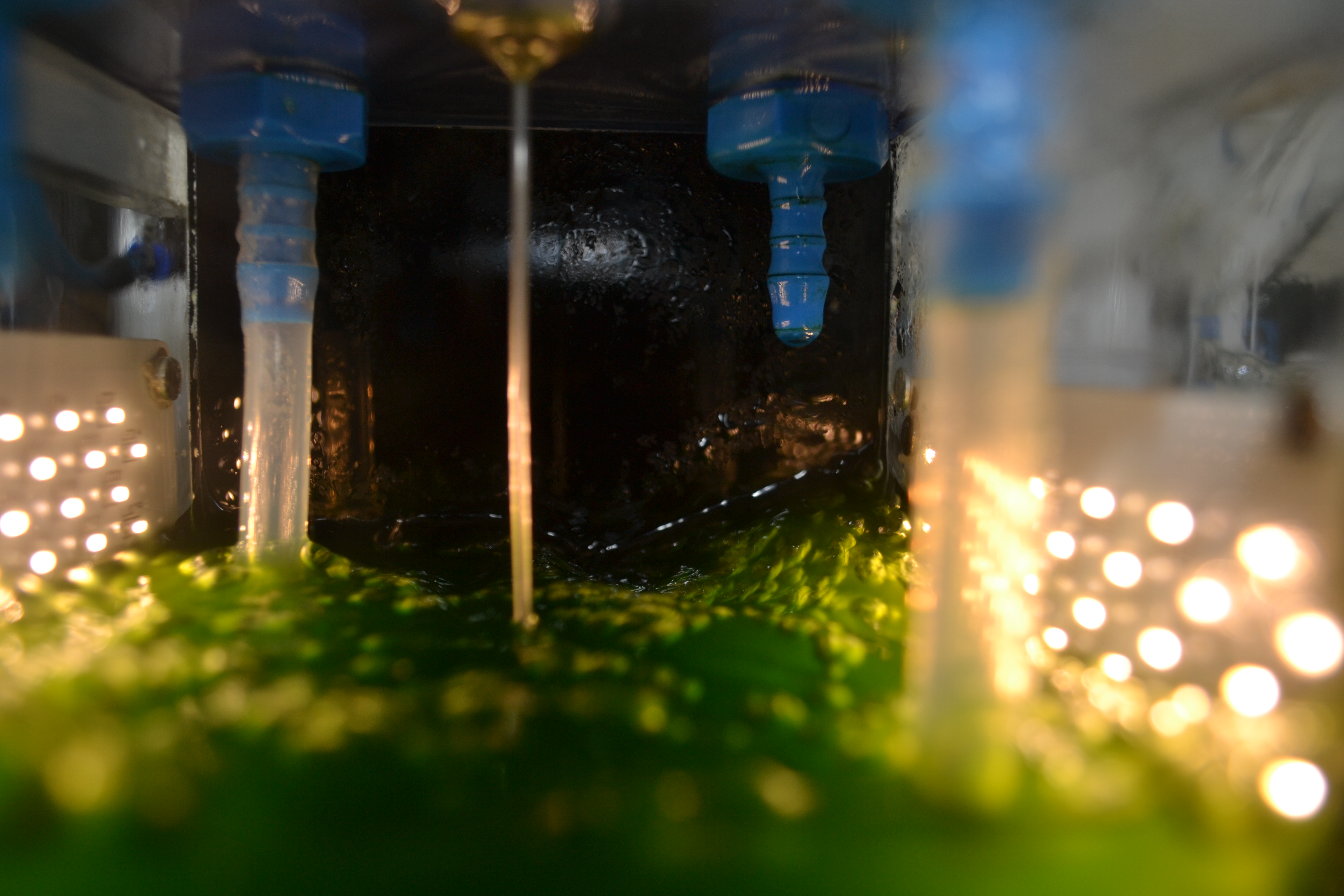

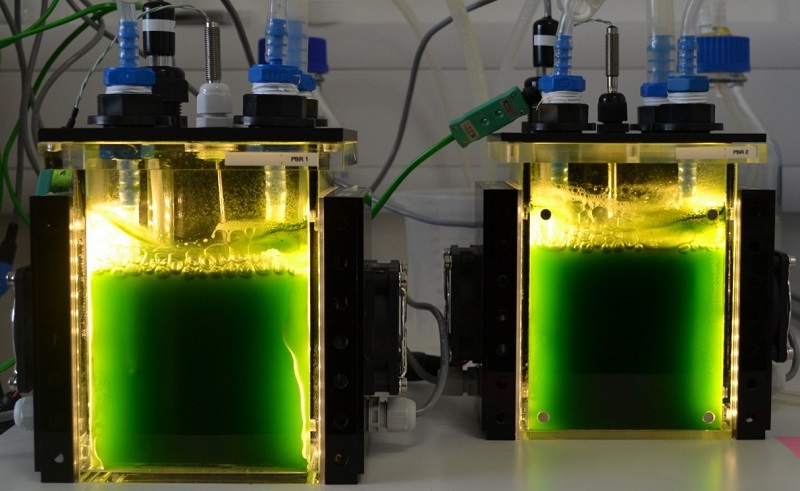

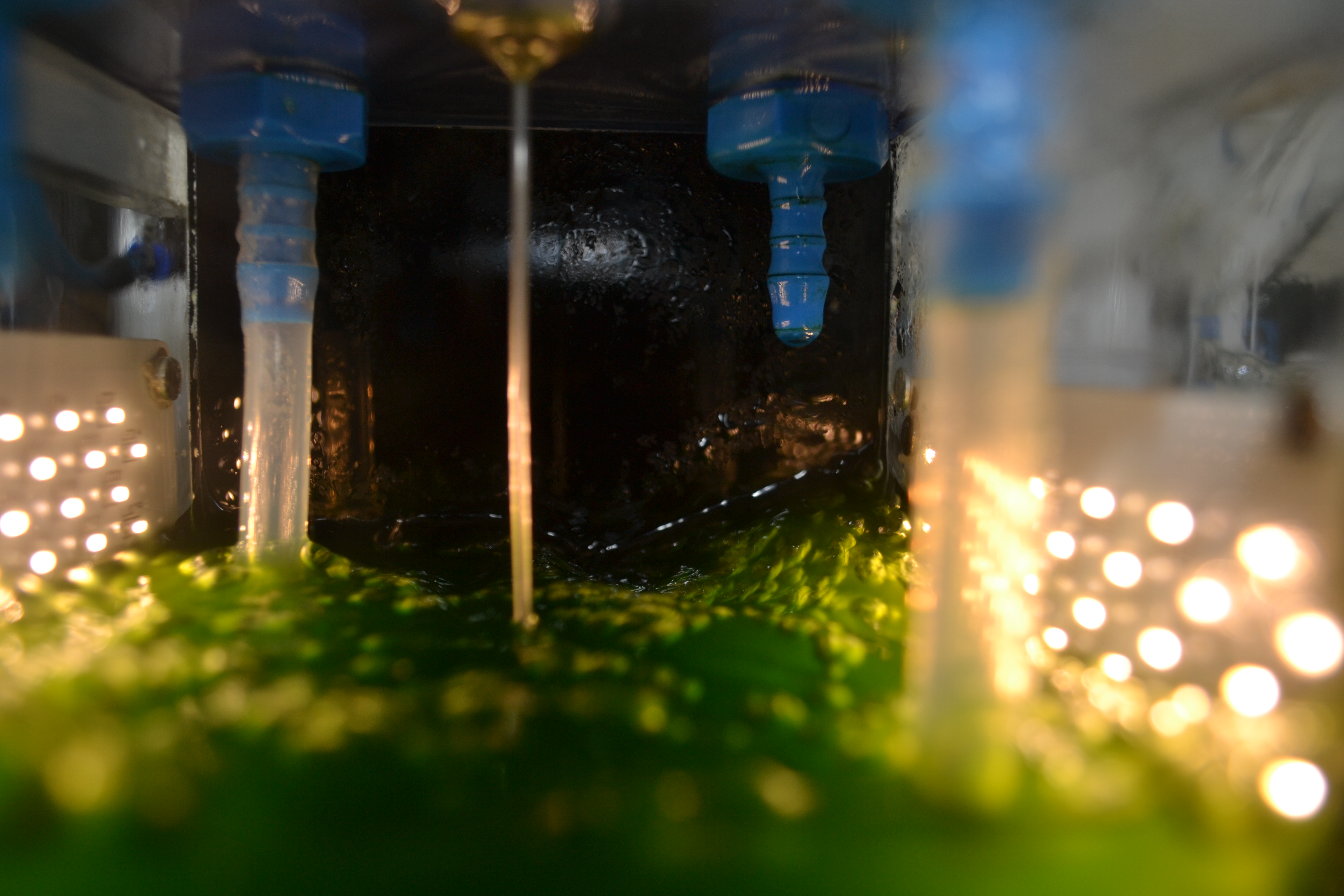

Xanthella have announced the launch of an upgraded version of their easy-to-use and highly flexible lab-scale photobioreactor system, the microPharos PBRTM. This system is ideal to conduct lab-scale research experiments on a very wide range of photosynthetic organisms including microalgae, cyanobacteria and higher plant cell cultures (eg Arabidopsis). The starter system consists of a Zeus II ControllerTM that measures and maintains the culture conditions according to user-defined specifications and the two airlift 1 litre tanks lit by LED light tiles. It also includes all the equipment necessary for temperature, pH and gas control. Too often experiments are done without controlling all three of these parameters making it difficult to have confidence in the results. The different components of the photobioreactors are very easy to assemble thanks to a clever magnetic design. The amount of light provided to the culture is easy to accurately measure since the sides of the tanks are flat producing a simple light path of 5cm. The culture parameters that can be regulated in the starter system are:

– pH, using pH probe and CO2 injection;

– Temperature, between 18 to 40°C (standard version – a low temperature option is also available);

– Light intensity from 20 to 1500 µmol photon/s/m2;

– Light/dark cycles, tracking and flashing light.

The starter systems cost £5,900 plus VAT and with free shipping within Europe, making the microPharos PBRTM the most cost-effective system for laboratory scale research. The system can also be easily upgraded to add more PBRs or change the types and wavelengths of the LED light sources as an example.

Don’t hesitate to contact Xanthella for more information or a demonstration, at the following address: info@xanthella.co.uk

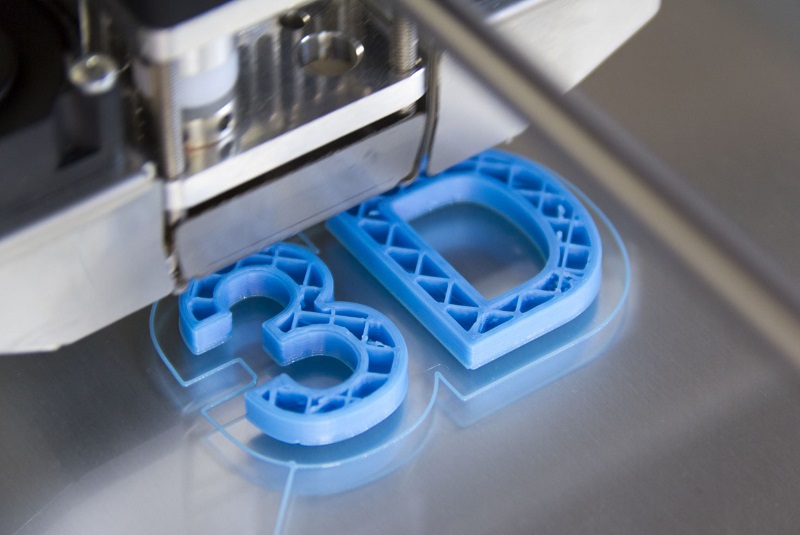

3D printed products made from algal biopolymers could herald a new era for design and manufacturing.

Two Dutch designers, Eric Klarenbeek and Maartje Dros, have created a polymer made of algae that can be used to produce 3D printed objects. The algal bioplastic is made of locally grown algae, e.g. Spirulina, which is dried and processed in either their AlgaeLab at the Luma Foundation in Arles, France or their design studio in Zaandam, the Netherlands. The designers believe that the local algae polymer could be used to make everything from shampoo bottles to tableware or rubbish bins, eventually replacing fossil oil-based plastics entirely. Their ambition is to provide all restaurants and catered events with tableware from the AlgaeLab. Algal filaments for 3D printing are also being produced by sustainability-focused enterprise, ALGIX 3D. Their ALGA filament, which is suitable for many 3D printing applications is produced in the Solaplast bioplastic production facility located in Meridian, Mississippi, along with a number of other bio-based resins and materials.

There are many environmental benefits to algal based biopolymers. Cultivation of algae removes carbon dioxide from the atmosphere, resulting in a material which is potentially not just carbon neutral but carbon “negative”. Using the algal biopolymers in manufacturing means everyday items can become mitigators of CO2 and help combat climate change.

Combining the low carbon benefits with the 3D printing process, which has the potential to put production into the hands of the consumer, could revolutionise manufacturing industries. Most manufacturing processes are priced on the materials used which often includes vast proportions of waste, even with maximised efficiency. As 3D printing can eliminate waste one 3D printed item can be produced at the same cost as one in 10,000.

Klarenbeek and Dros would like to see “3D bakeries” where everyday products are produced on demand from organic based polymers. This potential 3D production industry would not be a large centralised company but locally situated manufacturers using materials produced and available in the vicinity.

In conjunction with Ecovative, Klarenbeek has already marketed a fungus-based (mycelium) material and products, www.krown-design.com, which can be grown at home to produce a variety of household objects including tables, lamps and planters for the garden, as well as packaging and insulation.

Some of the 3D printed algal items produced in the AlgaeLab have been on display at the Museum Boijmans Van Beuningen in Rotterdam as part of an exhibition called Change the System. Further work is ongoing to develop algal “glass” which could be used to produce replicas for the museum.

Click the links to discover more about using algae in 3D printing and other designer ideas.

The ENBIO team from Xanthella and ALIenergy are delighted to be finalists in this years VIBES – Scottish Environment Business Awards.

VIBES recognises business commitment to tackling environmental challenges. Now in the 19th year, the VIBES awards urge Scotland’s businesses to challenge their everyday working practices and embrace the economic opportunity of sustainability. Amongst the diverse businesses which have previously succeeded in demonstrating their contribution to Scotland’s sustainability are Wood, Changeworks, Diageo (Leven), The Glenmorangie Company Ltd, and the Royal Zoological Society Scotland.

The finalists have been selected across nine individual award categories which aim to recognise the different ways organisations are implementing environmental best practice in their daily activity. This could range from reducing the use of plastic or developing a new product or service, to encouraging cycle to work schemes or replacing company vehicles for electric cars.

Click here for more details and full list of finalists in all categories.

The winners will be announced at an awards ceremony to be held on 14th November at the Radisson Blu in Glasgow.

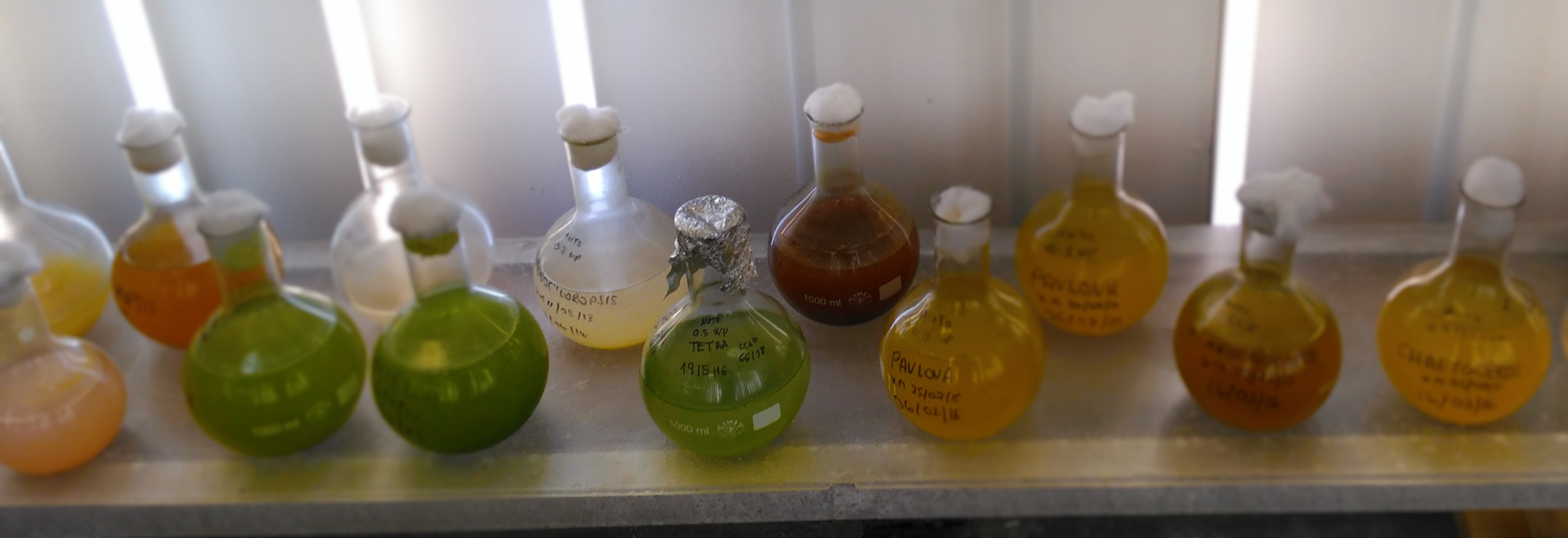

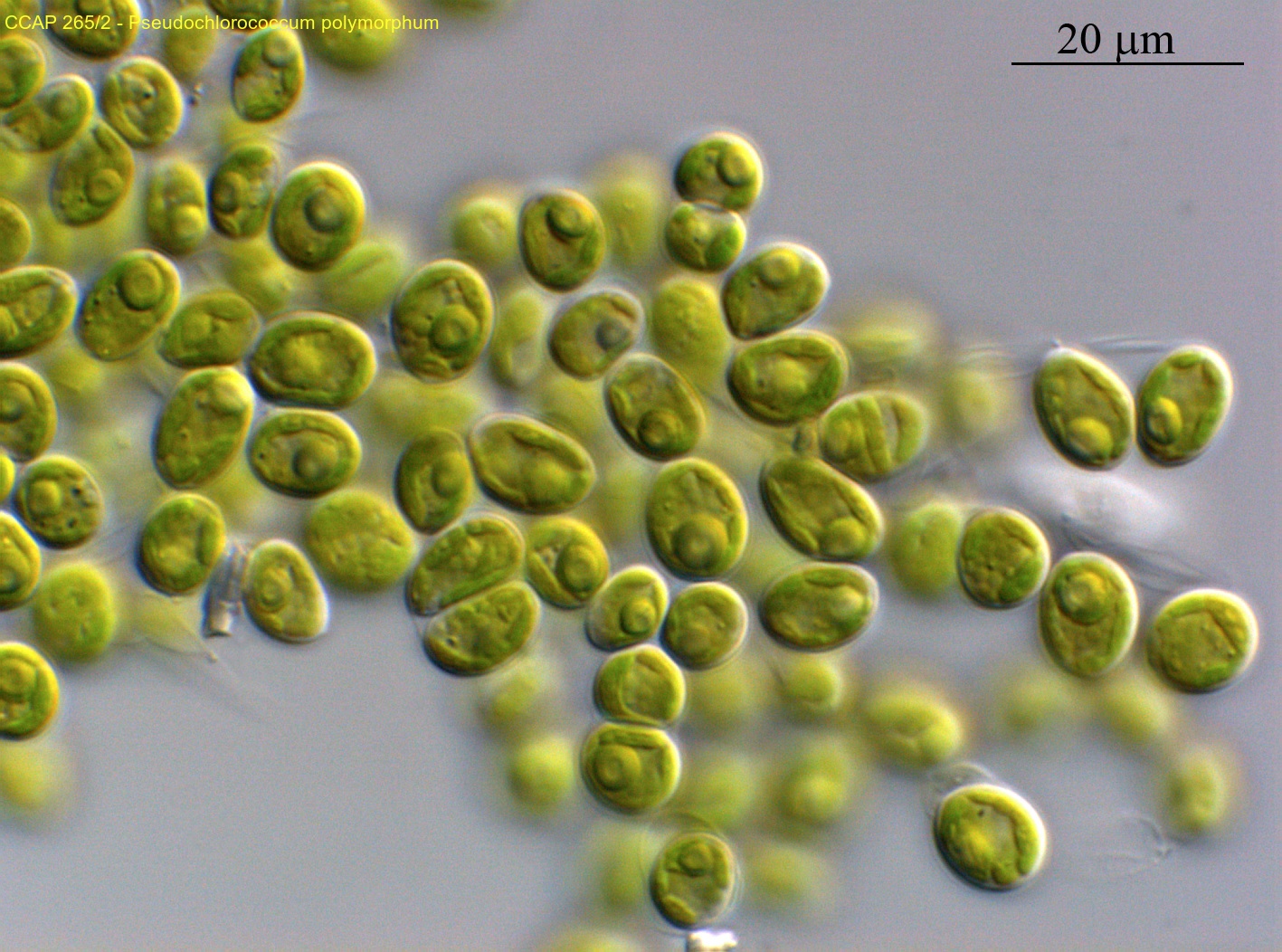

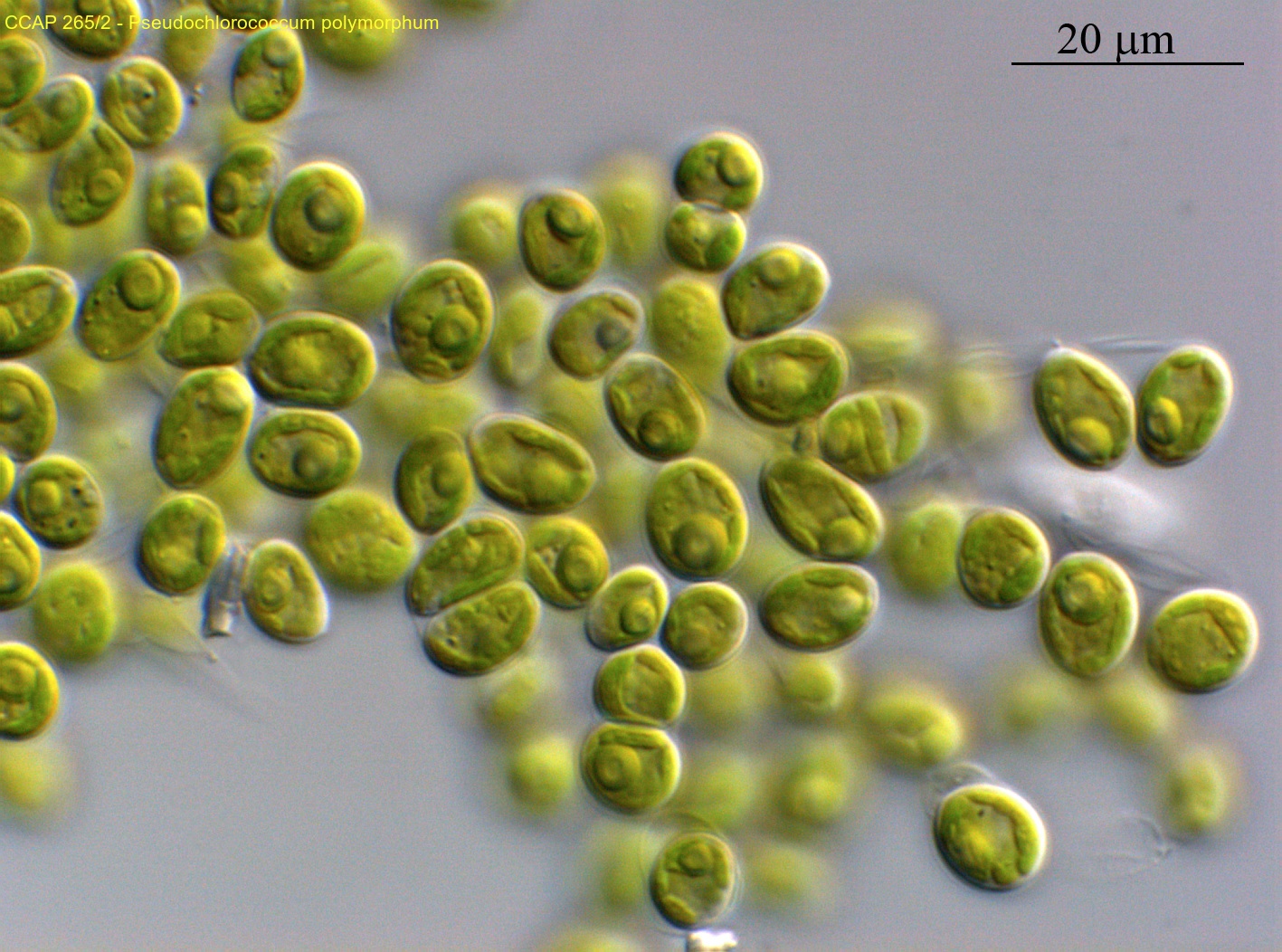

Swedish Algae Factory has been cultivating a particular group of microalgae, called diatoms, and investigating their potential uses.

Diatoms are a huge group of photosynthetic microalgae that are found in almost every aquatic environment on the planet. With thousands of species, diatoms are amongst the most abundant and ecologically important microscopic organisms. They are responsible for approximately 20% of oxygen generation through photosynthesis, and can be recognised by their unique and beautifully elaborate exterior shells that contain silica.

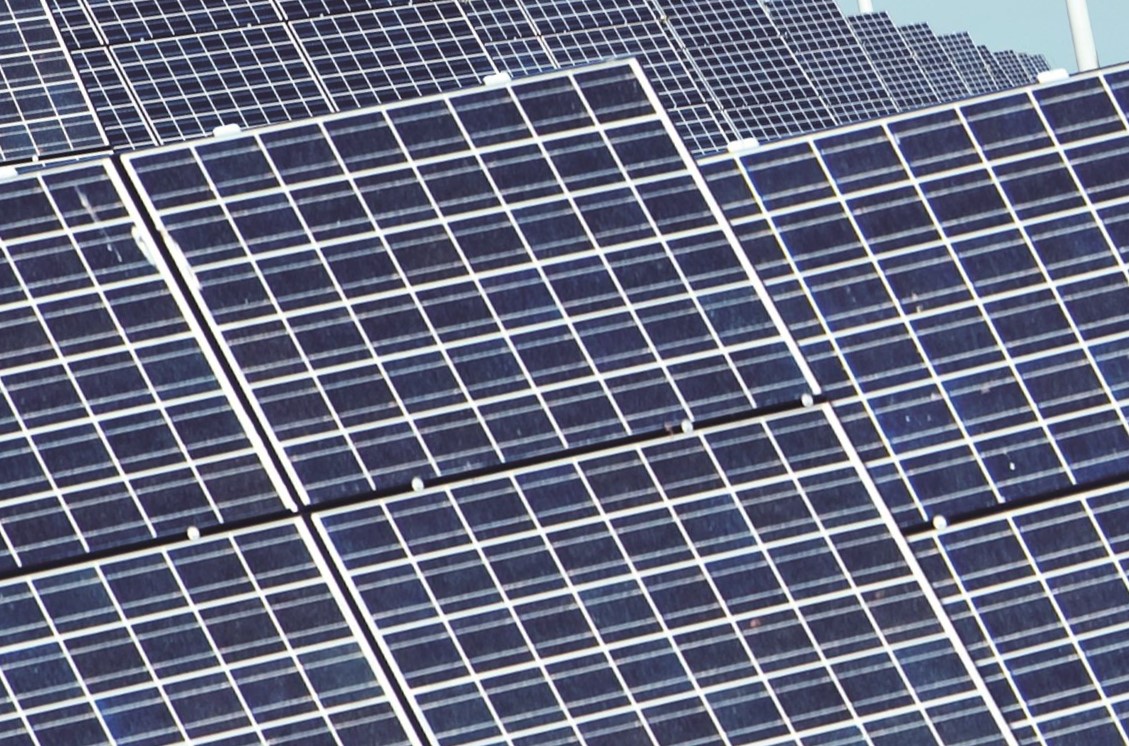

The Swedish Algae Factory have developed a protocol for production of nanomaterials made of silica from diatoms. The extracted materials have been tested on solar panels. The naturally light trapping silica has been shown to improve the efficiency of dye – sensitised solar panels (DSSC) by as much as 60%: click here for details of their work.

The Use of Nanotechnology in Solar Energy

Oman Centre, Swedish Algae Factory partner for diatoms

Plastics are a major part of modern everyday life, recent figures estimate around 3.7 million tonnes of plastic are used per year in the UK (Plastics Europe). A proportion of the plastic is recycled after use; however, many plastic products are used once then thrown away, particularly plastic packaging. This discarded plastic does not degrade and is making its way into the oceans and waterways all over the world.

In efforts to reduce the impact of plastic pollution, biodegradable plastic has been developed, which has a shorter lifespan than conventional plastic. This type of plastic is usually made from fossil fuel feedstocks with chemical additives to enhance the degradation process. There are specific conditions to the breakdown of these plastics; high temperature and UV light; and left over products can themselves be harmful to the environment. A potential alternative is using plant based polymers to make plastics, they produce bioplastics. The difference being that bioplastics are compostable and decay into natural materials that can combine with the soil. Some of the plants used for the bioplastics are also food crops, like corn or maize, creating competition between food and plastic. Companies have been looking elsewhere for sources of materials to make plastic and one of the possibilities is algae.

Over the last few years a number of manufacturers (e.g. Solaplast; Cereplast; Bloom) and collaborative groups (e.g. SPLASH ) have been investigating and developing algal polymers. A new generation of plastic algal feedstocks is available, and being used in a variety of renewable plastic resins suitable for numerous applications.

For further developments and news on algal bioplastics and their uses – follow the links below:

Algix: http://algix.com/from-plastic-pollution-to-an-algae-solution

Vivobarefoot Sports shoes: https://www.news18.com/news/sports/your-next-shoe-could-be-made-from-algae-1447973.html and https://www.wired.com/story/slip-into-earth-friendly-running-shoes-made-of-algae/

Journal of the North Atlantic and Arctic –https://jonaa.org/content/2018/01/19/algaibioplastics

Science Daily: https://www.sciencedaily.com/releases/2013/05/130527100524.htm

Xanthella is continuing to strengthen the expertise in the ENBIO project with the recruitment of a new product engineer, Dr Laurence Evans. His role will be to oversee the design and deployment of the Pandora PBR™ array at the facility on Ardnamurchan.

Laurence is a recent PhD graduate from Heriot-Watt University, with a keen interest in microalgae and their potential in bio-based industries. His PhD examined the application of microalgae in the treatment of municipal wastewater. The aim was to establish a low-cost treatment process compared to current conventional wastewater treatment. The work focused on enhancing the ability of the microalgae to reduce nitrogenous and phosphorus concentrations through environmental and biochemical factors. Before his PhD, Laurence had completed his undergraduate degree in biochemistry at the University of Bath. During his degree, he undertook two internships, one at University College London and the second at St. Judes research hospital, located in Tennessee, USA.

As product engineer at Xanthella, Laurence has already been involved in developing a 100L volume photobioreactor to increase the product range offered by Xanthella. A number of the new Pandora 100 “Odyssey” PBRs, with customised LED light sheets, were recently delivered to the Limerick Institute of Technology in Ireland.

Microscopic algae could hold the answer to the pothole nightmare that is blighting our roads.

A French collaborative programme, Algoroute, has been examining the production of bio-bitumen from algae. Using a process called hydrothermal liquefaction (pressurised water), waste algae is transformed into black, viscous bio-bitumen. The thick liquid has very similar characteristics to fossil-fuel based bitumen used on the roads.

The properties of the algal bio-bitumen suggest it could be an alternative for traditional bitumen used to bind aggregate on the roads and may be the future, creating “green” roads. Experimental trials and cost evaluations are being undertaken and further information will be available soon.

Watch this space…

For more details click here

ExxonMobil continues to fund a wide range of research into next generation biofuels, which includes the potential of algae. The work forms part of their ongoing examination of new technologies that will increase energy supplies, company efficiency and reduce carbon emissions.

Over the last 40 years algae have been widely studied as a feedstock for biofuel, as many species produce large quantities of storage oil products. The oil can be chemically modified to give a bio-diesel of similar composition to current transport diesel fuel. Cultivating algae has many benefits, including reducing green house gas emissions by direct incorporation of carbon dioxide; potentially higher yields of biofuel compared to other feedstocks and algal crops do not compete with food production for land or water.

ExxonMobil have a number of research collaborations focusing on algae-based biofuels and other non-food based feedstocks for biofuel with: Synthetic Genomics, Inc. (SGI), Colorado School of Mines and Michigan State; Renewable Energy Group (REG) and the University of Wisconsin.

Read more details of the research and development programme.

A new Algae Agricultural Act has been introduced to congress in the United States. The bill will give algal farmers the same advantages as farmers of traditional crops. The legislation reflects an increasing recognition of the potential of algae as an extremely useful agricultural crop for future food, feedstocks and the energy sector.

Read the full article

We’re looking forward to attending ALL-Energy this week

2nd and 3rd May at the SEC in Glasgow.

Drop in and say hello, we’ll be at

Stand Number HIE49

in the HIEnergy Pavillion.

Join the conversation @ASLEEproject16

#AllEnergy18 #abplacetob